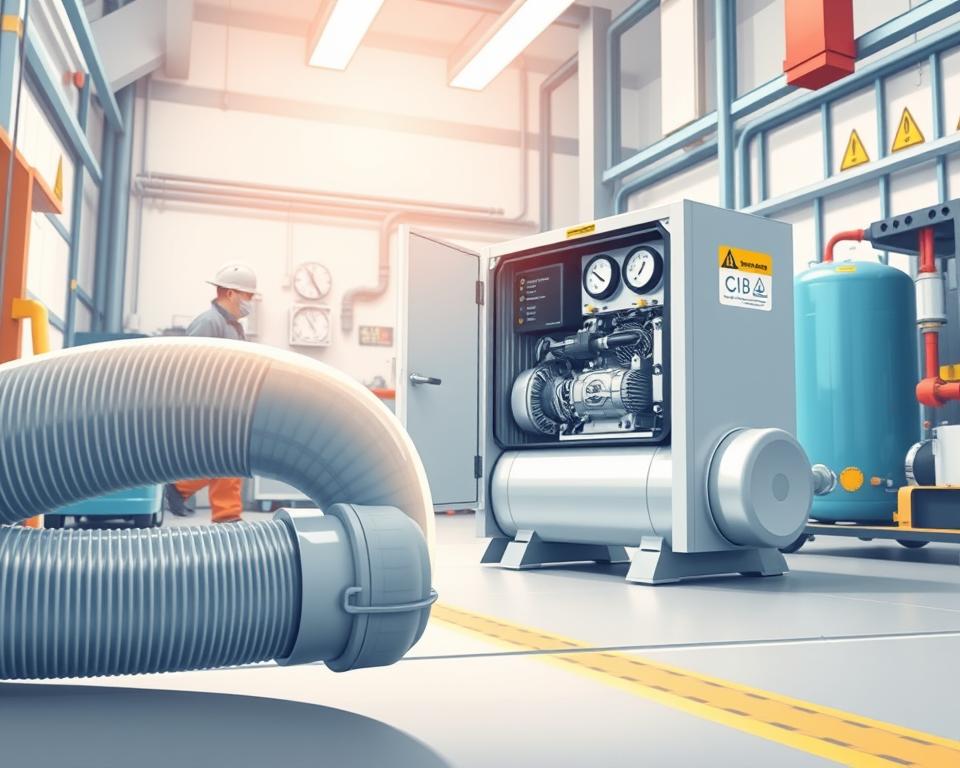

Your Complete Guide to PVC Pipe in Compressed Air Systems

Did you know that a ruptured compressed air system can release energy equivalent to a stick of dynamite? Countless operations remain oblivious to the risks of certain piping systems they employ. Here’s why you must prioritize safety over cost when selecting PVC air line.

Despite growing interest in certain materials, OSHA strictly prohibits their use in above-ground applications. Over time, exposure to oils and temperature changes weakens them, leading to catastrophic failures. Even at “safe” pressure ratings, the risk of explosions remains high.

Turn to Installation Parts Supply for sturdy aluminum systems. Using approved materials saves you from fines and enhances safety. Discover steps to construct a secure system.

Principal Conclusions

- Explosion danger leads OSHA to outlaw some pipe materials.

- Pressure ratings drop as temperatures fluctuate.

- Long-term exposure makes pipes prone to brittle breaks.

- Switching to aluminum vastly improves safety.

- Spending on correct materials avoids penalties and injuries.

Why PVC Pipe Is Dangerous for Compressed Air Systems

PVC makers caution never to employ it in high-pressure air setups. Unlike water, compressed air stores explosive energy—a ruptured line can release force comparable to dynamite. Select your piping wisely to avoid deadly failures.

- Brittleness: Sub-freezing temperatures turn materials brittle, increasing fracture risks.

- Adhesive failures: Temperature changes and oils cause adhesive joints to fail.

- Misleading ratings: Ratings halve by 110°F, a common shop temperature.

OSHA cites a $110,000 fine after a facility’s piping shattered, injuring workers. Compression heating lowers allowable pressure even more—often ignored.

“Above-ground use of certain plastics for compressed air violates OSHA standards due to explosion risks.”

In contrast, metal pipes deform before bursting. PVC shards fly far and fast, causing collateral damage.

Daily heat and cold cycles in a workshop degrade plastics rapidly. A decade’s UV and chemical attack weakens plastic, so small leaks too often balloon into disasters.

Safe Alternatives to PVC Pipe for Air Compressor Lines

Aluminum piping systems outperform traditional options in both safety and efficiency. They leak 90% less than black iron, making them ideal for today’s shops. Their lightweight design and corrosion resistance make them ideal for long-term use.

Threadless modular aluminum assemblies speed assembly. Prebuilt snap-together aluminum runs come from Installation Parts Supply. A Midwest auto plant cut labor costs by 40% after switching to this system.

- Copper: Best for cleanrooms due to natural antimicrobial properties. Requires soldering expertise.

- Stainless Steel: Resists rust in humid areas like coastal workshops.

- ABS/HDPE: For solvent-rich environments, ABS/HDPE stays intact.

“Our aluminum retrofit reduced energy waste by 15%—paying for itself in 18 months.”

Proper torque is critical. Cracks from overtightening and leaks from under-tightening are common. Follow manufacturer specs—typically 25–30 ft-lbs for aluminum joints.

Use NSF-certified materials when air quality is critical. Pick piping suited to your facility’s conditions.

Material Selection Guide for Compressed Air

Selecting the best material for your setup requires balancing cost, safety, and efficiency. Switching to aluminum saved a factory $12k each year. Here’s how to make the right choice.

| Material | Cost (per ft) | Maintenance | ROI Time |

|---|---|---|---|

| Aluminum | $8.50 | Low | 18 months |

| Black Pipe | $5.00 | High | N/A |

| Copper | $10.20 | Medium | 24 months |

Temperature matters. Plastics fail under 32°F; aluminum works from -40°F to 200°F. Use stainless steel where solvents are present.

Pro Tip: Use leak-loss math to estimate ROI. A 10% leak in a 50 HP system wastes $3,500 yearly.

- Don’t undersize—pick pipe rated at or above your compressor’s PSI.

- Verify your system meets OSHA welding and pressure-test rules.

- Get a complimentary piping audit from Installation Parts Supply.

“Our aluminum retrofit cut energy waste by 15%—paying for itself in 18 months.”

Small shops can DIY, but experts deliver guaranteed seals. Always verify warranty terms—some materials cover 10+ years.

Final Thoughts

Safety outweighs sticker price in compressed-air piping. Ninety-two percent of pipe failures occur in aging lines, frequently causing injuries. Aluminum offers 99.8% reliability, making it a smart long-term choice.

Remember:

- Never use pipes that can fragment violently.

- Choose rust-proof metals over plastics.

- Ignoring standards invites fines and insurance headaches.

Upgrade now and secure your workplace. Get instant quotes and special offers from Installation Parts Supply. Access a complimentary maintenance template or request urgent replacements.

Commit to safer piping today—your team’s safety depends on it.